This item is shown in the following options:

Estimated Delivery Price

Enter your zip code to get a delivery estimate.

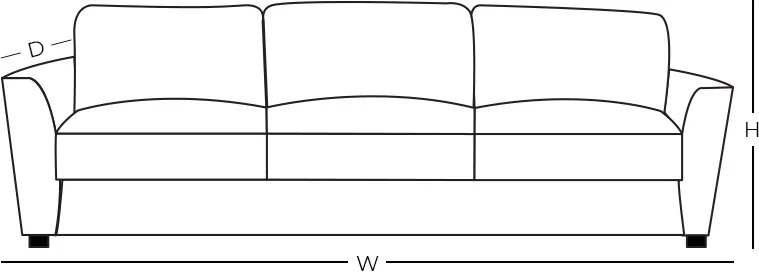

Dimensions:

83" W

×

39" D

×

36" H

Description

- Tapered Leg

- We use a POCKET SPRING seat cushion in the seat of the Bennett group. The pocket spring system is created by turning high tensile steel individual springs, which are then wrapped in their own singular pocket of fabric. You will find that each individual seat cushion contains a matrix of individually wrapped coil springs encased in a specifically designed foam shell that is covered in dacron fiber. The system has many benefits. The fabric pocket used allows each spring to slide up and down independently of it’s neighbors allowing for maximum comfort for more than one person on the sofa. The ultra high coil density allows maximum conformity to body contours. The POCKET SPRING system will allow each seat cushion to keep its uniformity over the life of the furniture. You will find the seat cushions to be loose (except for recliner) which adds to the versatility of the frame.

- Attached Back

Specifications

Specifications

Product

Motion Type

Stationary

Motion Type

- Stationary

Seat Depth Standard

Normal

Seat Depth Standard

- Normal

Dimensions

Height (bottom to top)

36" H

Height (bottom to top)

- 36" H

Width (side to side)

83" W

Width (side to side)

- 83" W

Depth (front to back)

39" D

Depth (front to back)

- 39" D

Seat Height

20"

Seat Height

- 20"

End Table Height

End Table Height

Seat Width

67"

Seat Width

- 67"

Seat Depth

23"

Seat Depth

- 23"

Style Elements

Custom Options

Custom Upholstery

Custom Options

- Custom Upholstery

Color Family

Brown

Color Family

- Brown

Leg / Base Type

Tapered Leg

Leg / Base Type

- Tapered Leg

Design Style

Transitional

Design Style

- Transitional

Seat Description

We use a POCKET SPRING seat cushion in the seat of the Bennett group. The pocket spring system is created by turning high tensile steel individual springs, which are then wrapped in their own singular pocket of fabric. You will find that each individual seat cushion contains a matrix of individually wrapped coil springs encased in a specifically designed foam shell that is covered in dacron fiber. The system has many benefits. The fabric pocket used allows each spring to slide up and down independently of it’s neighbors allowing for maximum comfort for more than one person on the sofa. The ultra high coil density allows maximum conformity to body contours. The POCKET SPRING system will allow each seat cushion to keep its uniformity over the life of the furniture. You will find the seat cushions to be loose (except for recliner) which adds to the versatility of the frame.

Seat Description

- We use a POCKET SPRING seat cushion in the seat of the Bennett group. The pocket spring system is created by turning high tensile steel individual springs, which are then wrapped in their own singular pocket of fabric. You will find that each individual seat cushion contains a matrix of individually wrapped coil springs encased in a specifically designed foam shell that is covered in dacron fiber. The system has many benefits. The fabric pocket used allows each spring to slide up and down independently of it’s neighbors allowing for maximum comfort for more than one person on the sofa. The ultra high coil density allows maximum conformity to body contours. The POCKET SPRING system will allow each seat cushion to keep its uniformity over the life of the furniture. You will find the seat cushions to be loose (except for recliner) which adds to the versatility of the frame.

Arm Type - Upholstered

Rolled Arm

Arm Type - Upholstered

- Rolled Arm

Back Cushion

Attached Back

Back Cushion

- Attached Back

Upholstery

Upholstery Classifications

100% Leather

Upholstery Classifications

- 100% Leather

Fabric Patterns

Solid

Fabric Patterns

- Solid

Upholstery Content

Upholstery Content

Construction & Materials

Seat Support Description

We incorporate in our suspension unit; heavy duty nine gauge sinuous spring steel. These “S” shaped steel springs are fastened to the top of the front rail and run from the front to the back of the piece two inches apart. These springs are attached to the frame using heavy duty clips. Two firm rods are used to hold the springs in place which offers additional durability to the sitting area, both on the front and the back of each individual seat. We also attach a canvas barrier between the foam and the steel springs. This does not allow the foam to wear. We use five steel springs per seat to ensure the strength, comfort and durability of the foam cushion core. In addition: we use two solid wooden stretchers that run front to back to stabilize and strengthen the frame against the tension of the steel sinuous springs. This adds to the strength of the frame itself.

Seat Support Description

- We incorporate in our suspension unit; heavy duty nine gauge sinuous spring steel. These “S” shaped steel springs are fastened to the top of the front rail and run from the front to the back of the piece two inches apart. These springs are attached to the frame using heavy duty clips. Two firm rods are used to hold the springs in place which offers additional durability to the sitting area, both on the front and the back of each individual seat. We also attach a canvas barrier between the foam and the steel springs. This does not allow the foam to wear. We use five steel springs per seat to ensure the strength, comfort and durability of the foam cushion core. In addition: we use two solid wooden stretchers that run front to back to stabilize and strengthen the frame against the tension of the steel sinuous springs. This adds to the strength of the frame itself.

Upholstery Frame Construction

The wooden frame on this collection is composed of Beechwood, and European Spruce in all load bearing areas and MDF in all non load bearing areas. These woods are selected at source and seasoned for a minimum of 2 years to ensure long term durability. All of the corners and load bearing areas of our frames are additionally secured with heavy duty corner blocks to add to the strength and durability of the frame. Upon completion of the construction of the frame, we encase the entire structure. This process ensures the strength and integrity of the frame. We the put one inch of foam around the frame before upholstery so that when you touch the sides and backs you notice a firm/soft sensation not four inches of play between the leather and frame as you would find with most of our competitors.

Upholstery Frame Construction

- The wooden frame on this collection is composed of Beechwood, and European Spruce in all load bearing areas and MDF in all non load bearing areas. These woods are selected at source and seasoned for a minimum of 2 years to ensure long term durability. All of the corners and load bearing areas of our frames are additionally secured with heavy duty corner blocks to add to the strength and durability of the frame. Upon completion of the construction of the frame, we encase the entire structure. This process ensures the strength and integrity of the frame. We the put one inch of foam around the frame before upholstery so that when you touch the sides and backs you notice a firm/soft sensation not four inches of play between the leather and frame as you would find with most of our competitors.

Item & Dimensions

Manufacturer

Luke Home

Manufacturer

- Luke Home

The Bennett Group Bennett Leather Sofa, made by Luke Home,

is brought to you by Esprit Decor Home Furnishings. Esprit Decor Home Furnishings is a local furniture store, serving the Chesapeake, Virginia Beach, Norfolk, VA area. Product availability may vary.

Contact us for the most current availability on this product.

Similar search terms: Sofa, Couch, Couches, Backless Sofas, Conversation Sofas, Conversational Sofas, Theater Seating, Theatre Seating, Home Theater Furniture, Angled Sofa, Davenport, Stationary Sofa, Stationary Couch, Home Theater Seating, Upholstered Sofa, Upholstered Furniture, Sofa Couch, Living Room Furniture, Furniture, Seating

Reference #: Bennett-S 3511